2025/03/17

Since its establishment in 2018, Lianyi Metal Products Co., Ltd. has started with precision casting window and door fittings and gradually expanded to high value-added fields such as non-standard metal parts and new energy lithium battery equipment accessories. In 2021, the company invested in the establishment of Lianyi Mechanical Equipment Co., Ltd., introducing large-scale multi-axis gantry machining centers and other equipment to achieve full industrial chain coverage of casting and machining. Currently, its products have been widely used in intelligent robots, special pumps, and shipbuilding, and provide core accessories for listed companies such as Softcont and Liyuanheng. The company adheres to the core concept of "innovation, integrity, and win-win," continuously promoting process upgrades and high-end transformation to become an industry benchmark enterprise.

2025/03/15

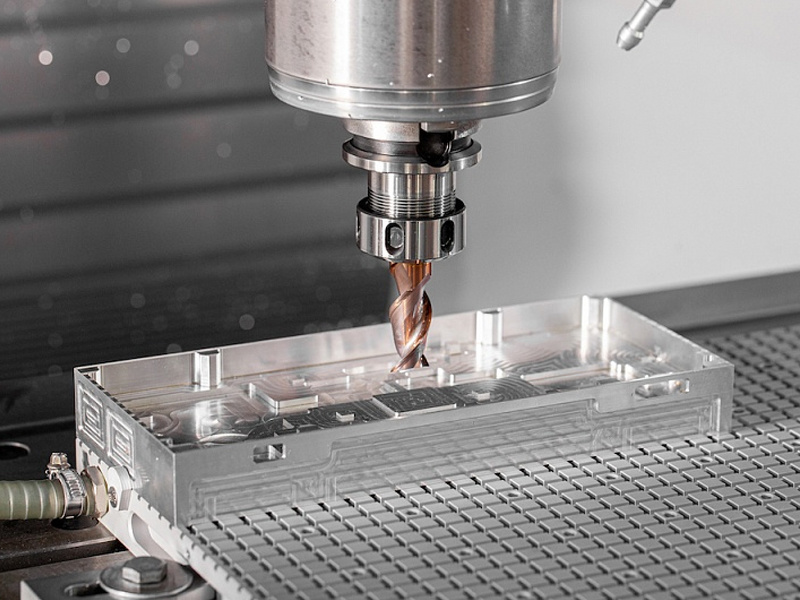

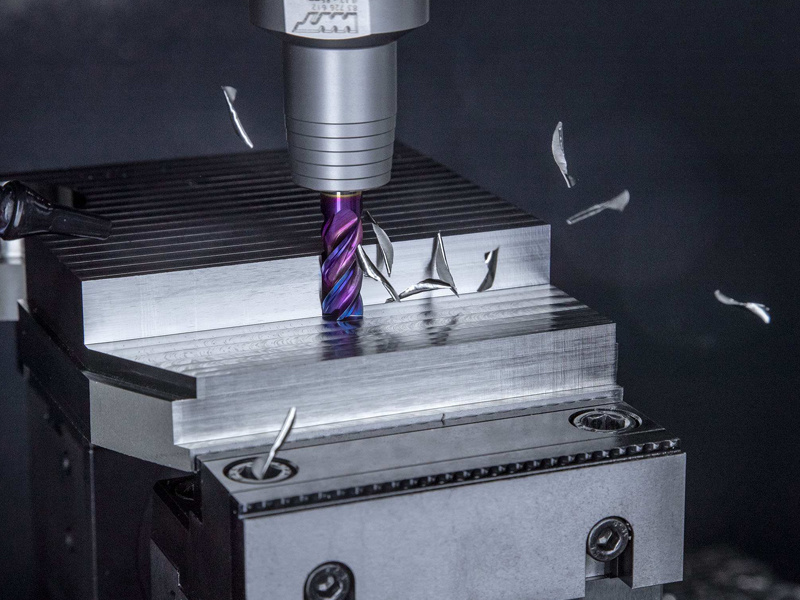

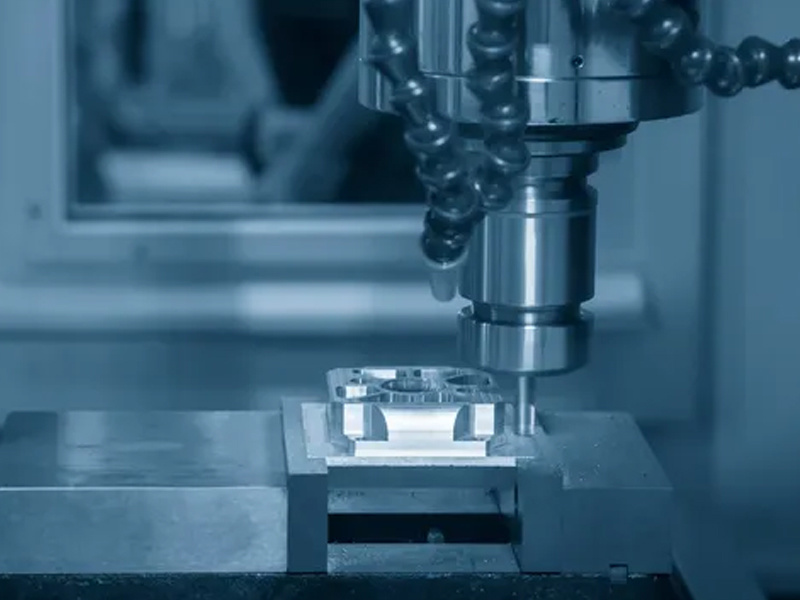

Lianyi Metal Products Co., Ltd. recently publicized details of its intelligent production workshop, covering the entire precision casting process, including waxing, melting, and spectral detection. By introducing automated equipment (such as large gantry machining centers) and digital management systems, the company has significantly improved production efficiency and product accuracy. At the same time, the workshop strictly adheres to the principle of "quality first", implementing high standards from mold shell cleaning to finished product inspection to ensure product qualification rate. This technological upgrade has not only consolidated its advantage in the non-standard metal parts market but also provided a solid guarantee for the large-scale production of new energy equipment parts.

2025/03/28

Innovation in Surface Treatment Technology for Investment Casting Metal Impellers

Significant progress has been made in the surface treatment technology of investment casting metal impeller. The new composite coating process enables the impeller surface hardness to reach over HRC60, and the wear resistance is increased by 3 times.

2025/03/28

Intelligent manufacturing technologies are rapidly becoming prevalent in the precision casting of metal pump bodies. By introducing a digital precision casting system, the dimensional accuracy of pump body production has been improved to ±0.05mm, and the defect rate has been reduced by 50%.

2025/03/28

Customized demand for investment casting metal static mixing core is increasing

The market demand for customized investment casting static mixing cores continues to rise. Due to the high flexibility of investment casting, special flow channel structures can be designed according to different mixing requirements. A chemical company stated that after adopting customized investment casting static mixing cores, its production efficiency increased by 30% and energy consumption decreased by 20%.

2025/03/28

The trend towards lightweight design of investment casting metal impeller is obvious

Investment casting metal impellers are developing towards lightweighting. Through optimized structural design and the use of new aluminum alloy materials, the newly developed investment casting metal impeller has reduced its weight by 25% while maintaining sufficient mechanical strength.

2025/03/28

Casting technology breakthrough improves the corrosion resistance of metal pump body.

The precision casting industry has made new progress in pump body anti-corrosion technology. A new type of pump body using a special alloy formula and precision casting process has performed exceptionally well in salt spray tests, with a service life three times longer than ordinary products.

2025/03/28

Investment Casting Static Mixer Core Promotes the Upgrading of Chemical Equipment

Investment casting static mixers are increasingly used in the chemical industry. These mixer components, formed by precision casting, can achieve uniform mixing of multiple media, with mixing efficiency increased by 40% compared to traditional products.

2025/03/28

Investment Casting Impeller Technology Innovation Promotes Water Pump Efficiency Improvement

Recently, the investment casting industry has made significant breakthroughs in impeller manufacturing. Impellers produced using a new investment casting process have a surface roughness of Ra1.6μm or less, improving hydraulic efficiency by over 30% compared to traditional processes.